Transforming Lives Through Excellence, Creativity, and Connection

Advancing Education and Innovation

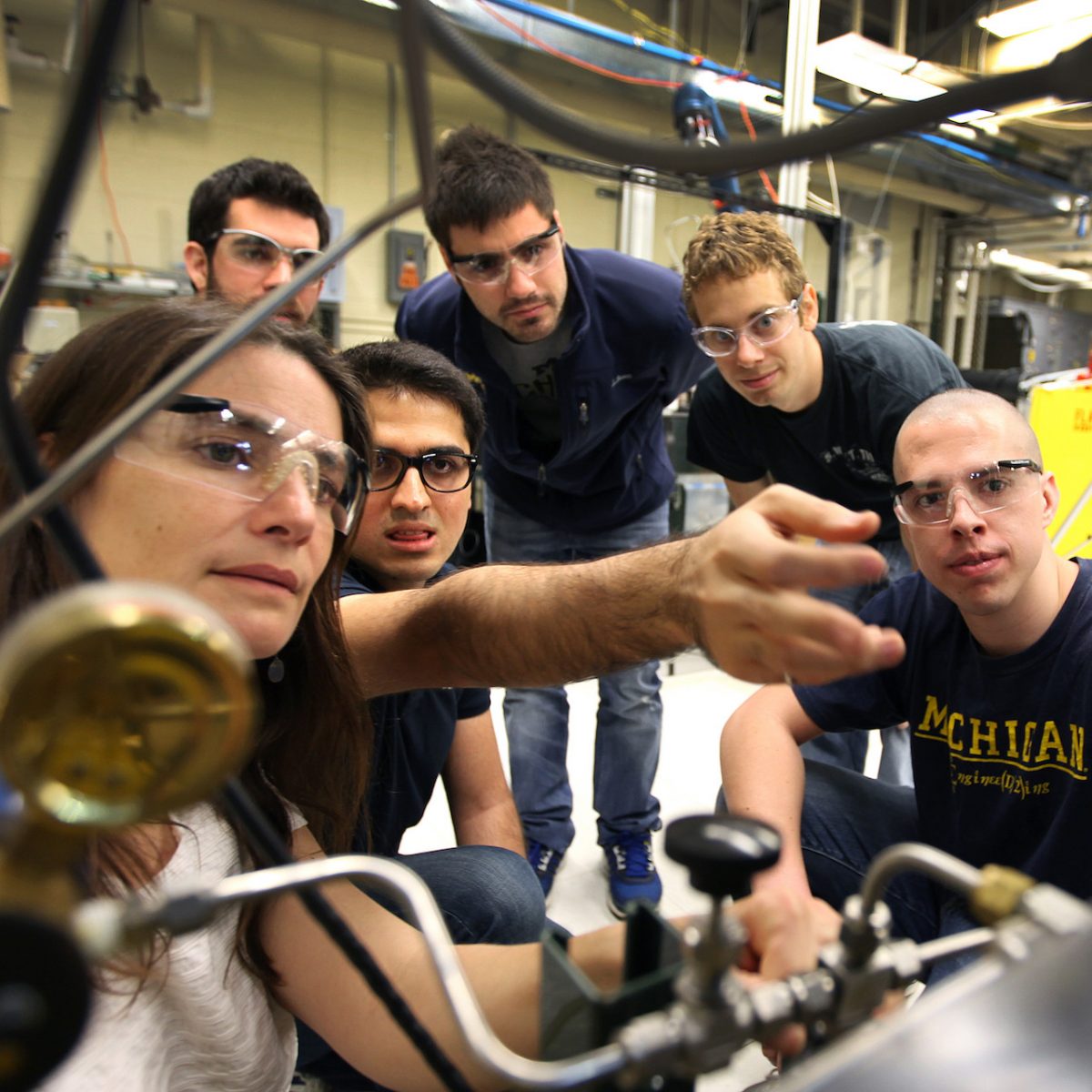

At Integrative Systems + Design, we educate and support a community of leaders, explore research breakthroughs for society, and advance knowledge in the field of engineering.

Our Master of Engineering degrees can be completed fully online from almost anywhere in the world, or on-campus here in Ann Arbor, Michigan. Our Design Science degree is only available on-campus.

Featured News

Top 3 in the Nation

Six Premier Multidisciplinary Graduate Degree Programs

ISD empowers leaders to transform our world in rapidly evolving industries through six premier graduate programs

Automotive Engineering

Master’s of Engineering (MEng)

The Automotive Engineering Program develops experts in the field who are poised to develop innovations that will change society and address global problems.

Design Science

Master’s of Science (MS) and Doctor of Philosophy (PhD)

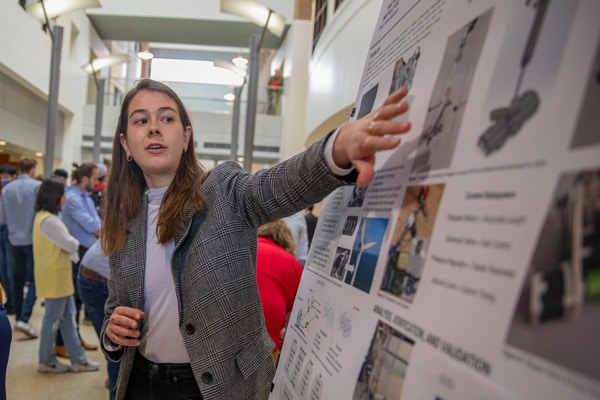

The Design Science Program at the University of Michigan engages in the systematic pursuit of design knowledge across all fields.

Energy Systems Engineering

Master’s of Engineering (MEng)

Energy Systems Engineering students take on the challenges facing society in the areas of sustainable energy generation, storage, and conversion.

Global Automotive and Manufacturing Engineering

Master’s of Engineering (MEng)

The GAME program seeks to develop engineers who are rooted in a strong background of product development and production, with a clear understanding of how to work with virtual global teams and deal with global supply chains.

Manufacturing

Master’s of Engineering (MEng) and Doctor of Engineering (DEng)

The Manufacturing program prepares leaders and engineers who are innovators in technology and have the broad knowledge and skills how to streamline manufacturing processes and make the managerial decisions.

Systems Engineering + Design

Master’s of Engineering (MEng)

Systems Engineering + Design equips students to enter the modern design processes in government and industry that integrate the work of diverse specialists into complex products and processes.

Explore Your Passions at a Premier Research Institution

The division of Integrative Systems + Design strives to study and promote leadership in the design and creation of innovative products and systems.

Upcoming Events

Connected Carnival: Driving Connected Innovation Theme Through DIY: ISD GSAC Career Event Sponsored by the CoE Office of the Associate Dean for Graduate and Professional Education

- Tuesday, April 23, 2024

- 1-3 p.m.

- SI North Commons Area, 1075 Beal Avenue

ISD Winter 2024 Graduation Celebration

- May 3, 2024

- 1:30 p.m. to 3 p.m.

- Chesebrough Auditorium, Chrysler Center, 2121 Bonisteel Blvd, Ann Arbor, MI 48109