Manufacturing

ISD's Manufacturing Program Is at the Forefront of Technologies That Move the World

Our world-class engineering and business faculty lead and conduct interdisciplinary research and teach and build advanced manufacturing technologies and integrative managerial skills for students. We challenge top students to become leaders and competitive engineers in Smart Manufacturing, which is defined as a “fully integrated, collaborative manufacturing system that responds in real time to meet changing demands and conditions in the factory, in the supply network, and in customer needs” defined by National Institute of Standards & Technology.

This degree can be completed fully online from almost anywhere in the world, or on-campus here in Ann Arbor, Michigan.

Why the ISD Manufacturing Program?

#7 Masters in Engineering (Industrial/Manufacturing) program that features concentrations of study in Production Systems and Quality Engineering; Manufacturing Design; Sustainability, Advanced Materials Design and Manufacturing; and Safety, Health, & Ecology

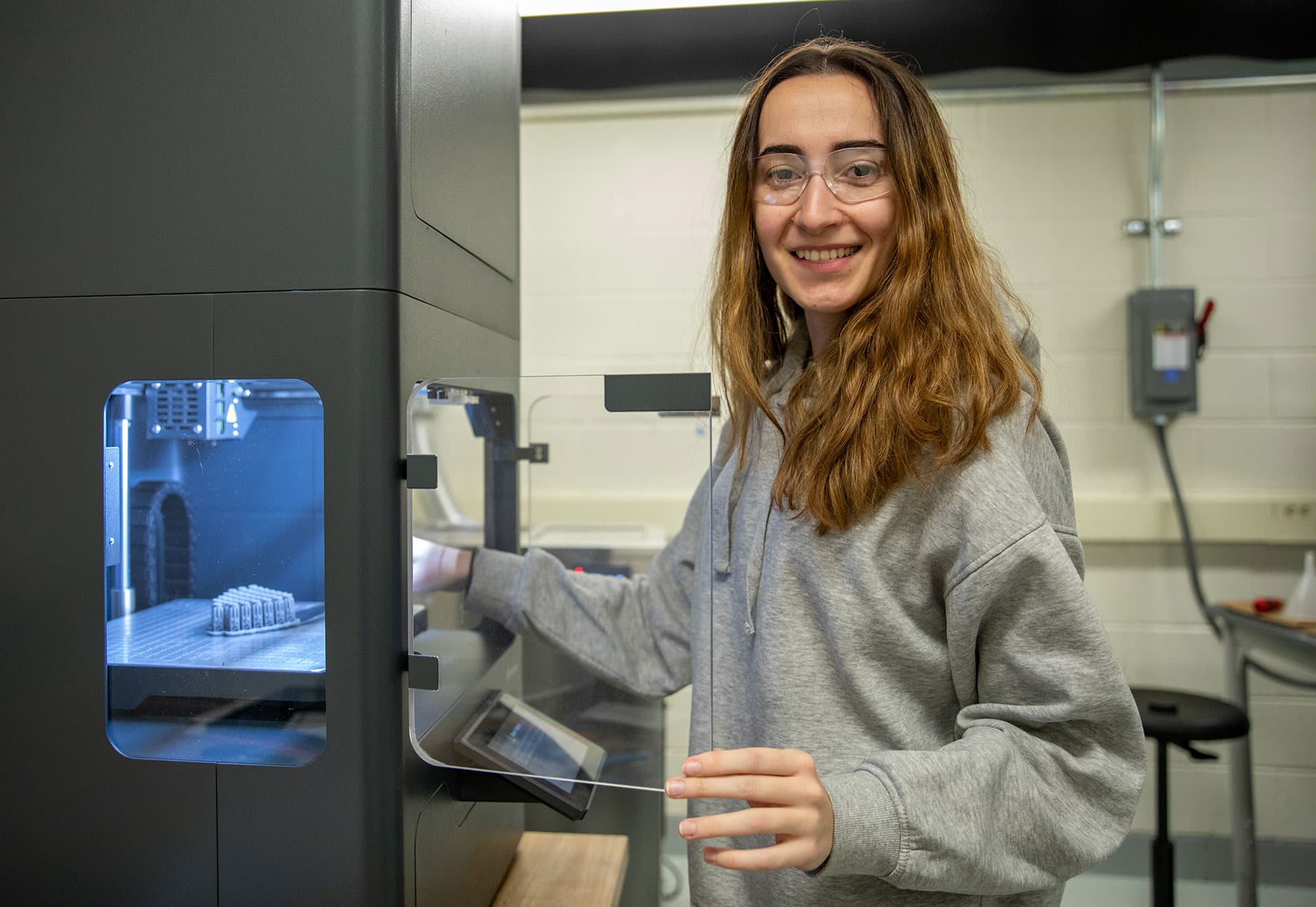

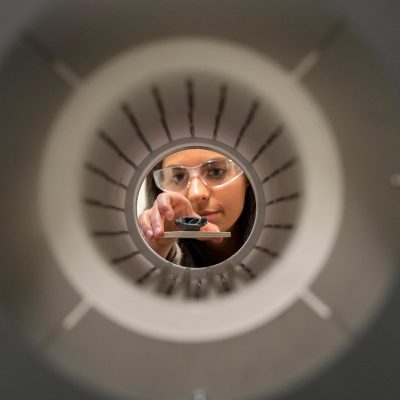

Work On the Cutting Edge

Become an innovator in technology and process improvement with resources and coursework on the cutting edge of Additive Manufacturing and 3D printing.

Our graduates with cross-disciplinary skillsets are well prepared for taking a technical leader and engineering manager position in the new era of smart manufacturing.

Dr. Judy Jin

ISD Program Director and Professor, Manufacturing

In this video, Chinedum Okwudire, U-M Associate Professor, Mechanical Engineering, Miller Faculty Scholar, talks about the benefits of ISD’s new Additive Manufacturing (AM) lab and how the field of AM is growing fast.

Master’s Degree and Other Program Options

Master’s of Engineering in Manufacturing

With an emphasis on recent advances in engineering fundamentals and practice, this degree prepares students to be innovators who can address global problems in this technologically dynamic and compelling field.

Doctor Of Engineering In Manufacturing

The Doctor of Engineering in Manufacturing (D. Eng. in Mfg.) is motivated by the need for technical leaders in the manufacturing arena who have depth in their own engineering disciplines, breadth across diverse engineering disciplines, breadth beyond engineering, the ability to lead project teams, and the skills to implement high-quality engineering research and development.

This degree is only available on-campus here in Ann Arbor, Michigan.

Sequential Undergraduate / Graduate Study (SUGS)

Undergraduate students at the College of Engineering in Ann Arbor have the opportunity to speed their progress towards an ISD Master of Engineering degree through the Sequential Undergraduate/Graduate Study (SUGS) program.

Dual Master Of Engineering In Manufacturing And Master Of Business Administration

In this dual-degree program, qualified students can pursue concurrent work in manufacturing engineering and business administration that leads to both a Master of Engineering in Manufacturing (MEM) and a Master of Business Administration (MBA).

U-M-SJTU Accelerated Master’s Degree Program (AMDP)

Students who receive an undergraduate BSE degree from the U-M – Shanghai Jiao Tong University’s Joint Institute (U-M SJTU) can also pursue an Integrative Systems + Design Engineering Master’s degree at U-M through the U-M-SJTU Accelerated Master’s Degree Program (AMDP).

Intersecting Industry Needs Through INCOSE Certification

The Integrative Systems + Design Division offers the opportunity for students to achieve INCOSE certification. This academic equivalency allows U-M graduate engineering students to bypass taking the certification exam to become certified system engineers, a major benefit.

Integrative Curriculum

In response to the uncertainty and volatility arising from the unprecedented evolution of the engineering field and its many industries, ISD collaborated with U-M’s world-renowned faculty and leading industry and government experts to revamp our curriculum.

Program Leadership

Judy Jin

Program Director, Manufacturing Program

Graduate Coordinator

Kathy Bishar

Graduate Coordinator, Manufacturing Program

Ready to Join Us?

If you are interested in applying to our Manufacturing program, visit our Admissions page.